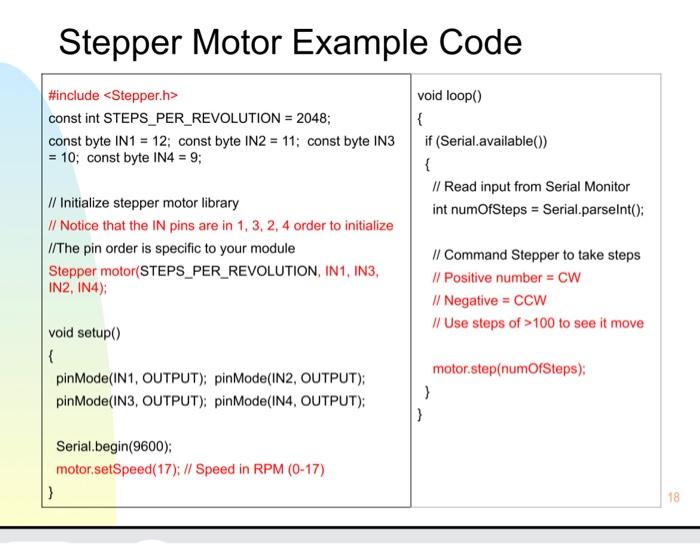

Stepper Motor Control Using PWM Technique Circuit Diagram Applications of Stepper Motors. Stepper motors are used in a variety of applications the place precision and control are paramount. Common use cases embody: - 3D Printers: For accurate layer-by-layer deposition of material. - CNC Machines: To control reducing tools and ensure precision in manufacturing. The use of robotics necessitates accuracy, and, as such, stepper motors are vital in ensuring motion control precision and accuracy. These motors are critical in applications that require precise movement control without variation. How to Control the RPM of a Stepper Motor. Adjusting the speed (or revolutions per minute (RPM)) of a stepper motor is important in most applications using stepper motors. The key to control lies in changing the frequency of the electrical pulses sent to the motor.

Stepper motors provide the precision control and reliability engineers need when they design robotic systems. For stepper motors to fulfill their potential in these applications, however, it's important to have a solid grasp of how to control stepper motors using the various methods of voltage control available. Stepper Motor Control Basics Stepper motors are ideal for applications that require speed and position control, especially at low speeds such as in automation, motion systems, and 3D printers. Due to their internal design which minimizes mechanical and electrical "delays" that occur in other motors, stepper motors have remarkable stopping accuracy and responsiveness.

What Is a Stepper Motor? A Newbie's Guide to Precision Movement Control ... Circuit Diagram

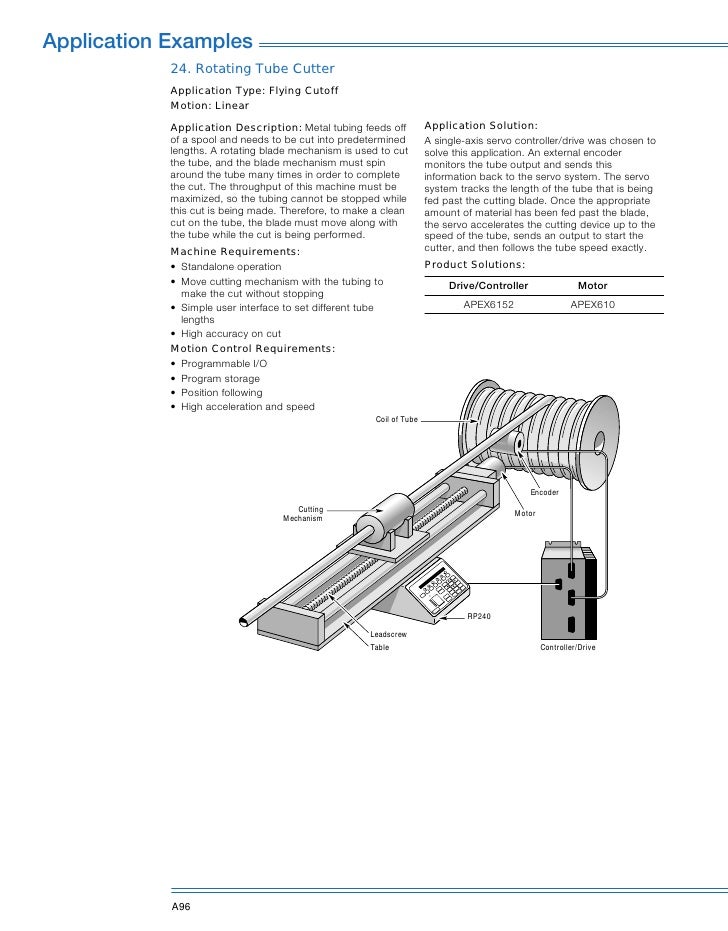

Case Studies Highlighting Precision and Control Benefits. One of the most noteworthy case studies is the application of stepper motors in a sophisticated photolithography instrument. In order to attain positioning accuracy of less than 10 nanometers, the stepper motors were coupled with a high-resolution feedback system. Stepper motors use specialized control methods to achieve better precision than standard variable speed motors, while avoiding the expense and complexity of servo systems. For industrial automation, the term motion control usually means using an electric motor to positively drive the position, velocity, and acceleration of a physical system Stepper motors are vital in precision applications where there is a need for smooth movement and high resolution positioning. Recognizing the differences between fullstepping, halfstepping, and microstepping control is essential for meeting these requirements. This article closes the knowledge gap by summarizing the basics of microstepping.

![[PDF] PLC AS A DRIVER FOR STEPPER MOTOR CONTROL Circuit Diagram](https://d3i71xaburhd42.cloudfront.net/ae2d020375639366ae2e5b35f0449f3a99d2b8b9/4-Figure3-1.png)

In applications where precision, smoothness, and quiet operation are critical, spread control plays a vital role in optimizing stepper motor performance. By implementing micro-stepping, either through direct control using a microcontroller or with the help of dedicated stepper motor drivers, you can finely manage the motor's movements.

How Stepper Motors Provide Precision Control Circuit Diagram

For many motion control applications, stepper motor solutions occupy the sweet spot for providing good precision and exceptional value. An AutomationDirect white paper titled Steppers Surpass Servos in Many Motion Control Applications describes stepper motor concepts, details, and applications where they are the best option. Following is a